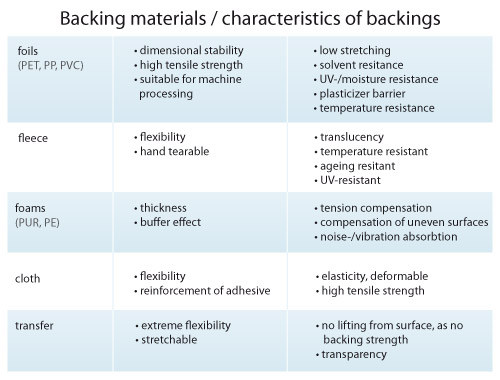

2.1 Backing materials

Backing materials are relatively thin, flexible materials, which are coated with adhesive.

The most common backings are:

- Paper Smooth or creped surface, variously expandable

- Cloth

- rayon, cotton, polyamide or fibre glass

- non-treated: tearproof, flexible and temperature resistant

- treated: e.g. for higher stiffness for better processing

- top coated: e.g. for protection against moisture and abrasio

- Films

- soft-PVC: flexible, soft, good insulation.

- rigid-PVC: dimensionally stable, UV- and moisture-resistant, imprintable

- hydrate-cellulose: can be torn by hand, not moisture resistant, easy to process.

- polyester: tearproof, abrasion-, ageing- and temperature-resistant,.

- polypropylene: flexible, tearproof, moisture resistant

- polyethylene: expandable, environment friendly. Self rotting when exposed to UV-light.

- Foams Specifically with light cellular structure; cells can have different sizes and can be open or closed

- Polyurethane soft, flexible

- Polyethylen resistant against solvents

- Non-Wovens temperature resistant, can be very thin, adapt well to uneven surfaces.

- Laminates Composite of two or more different materials, e.g. foam and PE-foil, thereby improved total properties

2.2 Adhesives

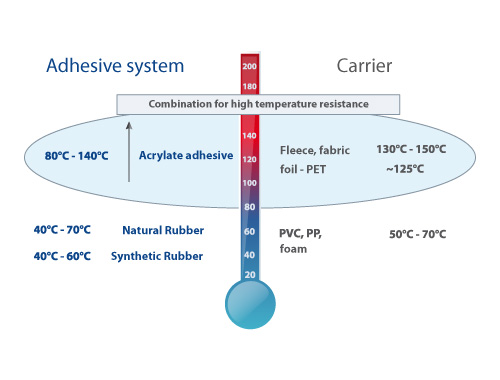

The characteristics of adhesives are mostly influenced by the basic materials. In general in adhesive technology it is differentiated between rubber-resin and polyacrylate glues.

- Synthetic and natural rubber Good initial tack, good removability is possible, good bond on critical surfaces like PP or PE.

- Pure Acrylic Temperature, aging and UV resistant, good resistance to chemicals.

- Modified Acrylate Adjusted by additions, mainly resins, to specific adhesive properties. Temperature, ageing and UV-resistant. Good resistance to chemicals; also suitable for permanent bonding on critical surfaces.

- Acrylate dispersion Solvent-free, watery acrylic adhesive, environmentally friendly production; temperature- and UV-resistant.

- Silicone Extremely temperature- and ageing resistant; for bonding on antiadhesive surfaces like silicone.

2.3 Liner

- Siliconized Paper Smooth, moisture-resistant, mainly liner for double-sided adhesive tapes.

- Siliconized Foil Smooth, moisture resistant, highly flexible and resilient, e.g. for automatic processing, mainly liner for double-sided adhesive tapes.

- Creped Siliconized Paper, Creped Siliconized Film, Embossed Siliconized Film Low surface contact, thereby easily removable, very flexible

- Embossed Foil not siliconized Is used, where siliconized materials can not be used. Small contact surface, therefore easily removable.

2.4 Backside Coatings

Reverse side coatings improve the unwinding performance of the tapes. They prevent the adhesives rewinding (i.e. during the dispensing of the tape adhesive remains on the back of the carrier material).

2.5 Primer

Many backing materials (e.g. PE) cannot be directly coated with adhesive, as they would not stick. Pre-treatment with a primer provides a secure connection between carrier and adhesive and therefore for reliable bonding and residue-free removal.